- +91-9999-35-31-38

- teknotradingllp@gmail.com

Product

Our Products

We are a Full Service Electrical

Contractor

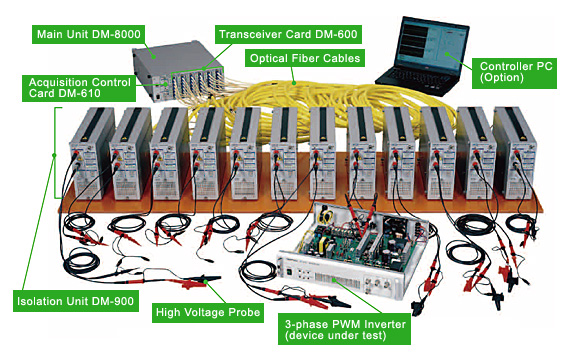

Isolation SystemDM-8000H

Supports wide-band, multi-channel simultaneous measurement and ultra-high-voltage floating measurement. Features:- 1. Frequency bandwidthDC~500MHz 2. Multi-channel simultaneous measurement(2ch~24ch) 3. High voltage measurement and operation parts are separated with fiber-optic isolation 4. The high voltage measurement part is battery operated (continuous operation for about 12 hours)

Heavy Duty Metal Detectors AD-4971-IP69K Series

These systems are full washdown (IP69K) rated. They come with fully integrated conveyor belt. For a complete list of available sizes see below. If mechanical reject is required please inquire.

Alternating Current Switching Power Supply

Wave WS-NCV Series --WaveSeries-- Phase control's electric control adjuster is possible to control even by the difficult control field. Becuse output voltage phase is sine wave. Specifications The stabilizing supply conduct adjustment of voltage that AC power does direct switching. Phase control's electric control adjuster is possible to control even by the difficult control field. Becuse output voltage phase is sine wave.

Yokogawa WT310 Digital Power Meter

The Yokogawa WT310 Digital Power Meter provides a wide current input range, fast display, and rapid data update rate in a compact and powerful instrument. High performance and reliable power measurement make it the preferred power meter in numerous industries from production lines to R&D applications.

Humidity Test Chamber

A humidity test chamber is a device used to simulate and control the humidity in an enclosed environment in order to test the effects of humid environments on materials, products, and components. The chamber is usually equipped with a humidity control system that can accurately measure and control the relative humidity inside the chamber. The humidity levels can be adjusted to simulate a wide variety of environmental conditions, from dry desert conditions to tropical rain forests. Such chambers are used in the testing of electronic components, automotive parts, textiles, and many other materials.

(SST) Salt Spray Test Chamber

Salt Spray Test Chamber (or salt fog test) is a standardized and popular corrosion test machine, used to check the corrosion resistance of materials and surface coatings. Usually, the materials to be tested are metallic (although stone, ceramics, and polymers may also be tested) and finished with a surface coating that is intended to provide a degree of corrosion protection to the underlying metal.

NOISEKEN Impulse Noise Simulator INS-4020/4040

The NoiseKen's Impulse Noise Simulator INS-4020/4040 is a further development from our versatile INS series simulators for greater ease of use, durability and reliability with new technologies specifically applied to this new product. The most significant addition is automatic ramp operation in output voltage, pulse repetition period and phase angle placement. Model: INS-4020/4040

ESD SimulatorESS-S3011A & GT-30RA

Free you from the hassle of testing by the pre-check function and the weight reduction of the discharge gun EMC test equipment to evaluate the resistibility of electronic equipment when energy charged on a human body or object is discharged to the electronic equipment. This can be available for evaluating malfunctions or functions declines of electronic equipment against the ESD. Programmable simulator to ease some complicated tests. The output voltage is up to 30kV allowing to perform testing compliant to IEC61000-4-2 & ISO 10605 Standards.

GW Instek GDM-9061 Digital multimeter

The GW Instek GDM-9061 is a 6 1/2 digit digital multimeter with extensive functionality. The meter offers a high precision DC voltage measurement and features a total of 11 other accurate measurement functions. Furthermore, this meter also has a large number of Math- and statistical functions to simplify the analysis of data. In addition to the standard numerical display mode, this meter also offers a wide range of graphical functions such as a barmeter, trend graph and histogram. A very unique feature of the GW Instek digital multimeters is the ability to simultaneously perform two different measurement functions. The functions are executed parallel to each other and the measurement results are displayed separately as numerical values or graphs.

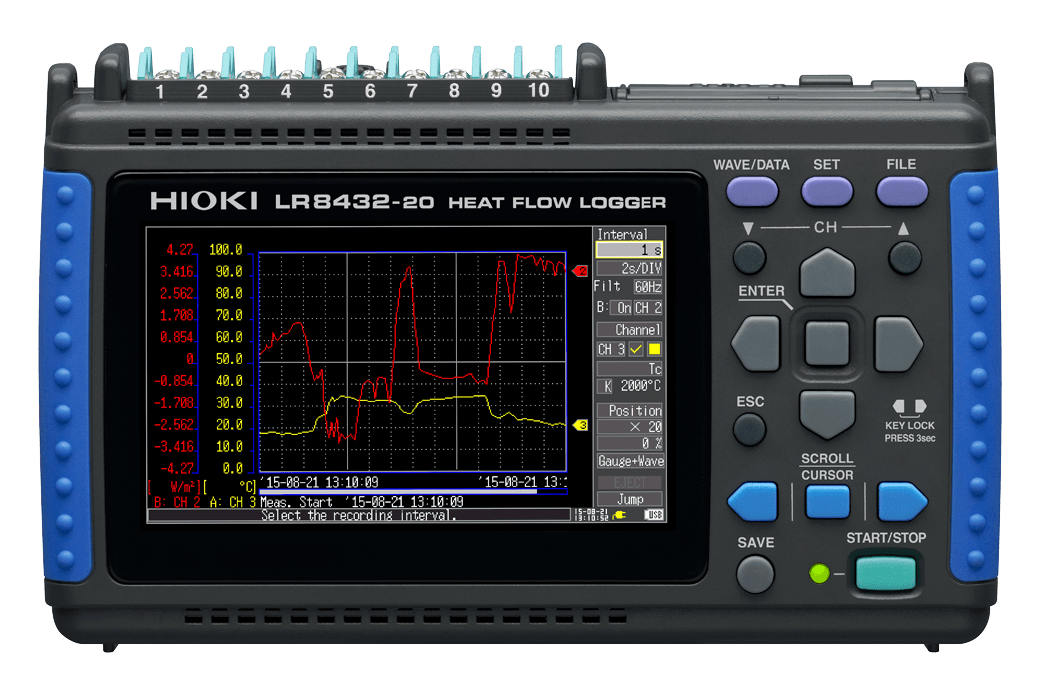

HEAT FLOW LOGGER LR8432

Compact & Lightweight Heat Flow Logger for Analyzing the Causes of Temperature Change. Use a heat flow sensor to measure the movement and volume of heat energy. measure of temperature and voltage.

DIGITAL MULTIMETER DT4223,DT4224

Pocket DMM that Prevents False Circuit Breaker Trips using Proprietary Technology.

LCR METER IM3523

Ideal for Production Lines of Electronic Parts and Automated Testing. Testing source frequency: 40 Hz to 200 kHz. Measuring time: 2 ms

ZTS-1 Digital Force Gauge

Standard Features EL electro luminescent display is highly visible in dark locations Multi-langauge program menus: English, Chinese, Korean, German, French, Italian, Spanish, Japanese Export gauge memory or save continuous data to USB flash drives Display force and displacement data with Imada FA test stand 30,000 data/sec ultra-high sampling rate; Processes and transmits 2,000 data/sec. Color-coded LED indicators and output signal for Go/No Go testing Ergonomic design with non-slip grips, heavy duty metal construction Capacity up to 1,100 lbs (push/pull) Overload capacity 200% of F.S. ZT Digital Force Gauges feature a brand new intuitive user interface with easy-to-use menus. Select units, reverse the display, set high/low setpoints, and set all other functions using plain language menus.

FSA-K2 Material Tester

Integrated Force & Displacement Testers Standard Features Ultra rigid, 0.5 mm deflection at max. load Selectable Manual, Increment, Single Cycle, Continuous Cycle and Force Control Easy-to-program menus control speed, cycles, pause duration, high/low setpoints, time, auto start displacement, etc. Highly visible EL electro luminescent display Color-coded LED indicators and output signal for Go/No Go testing Processes and transmits 2,000 data/sec. USB, RS-232C, Digimatic, Analog outputs Force Units: lbf, kgf, N (selectable) Displacement Units: inch, mm (selectable) 1,000 data memory for recall or download Tester includes Force-Recorder Pro software, cable, full set of standard attachments, AC adapter/charger, and calibration cert traceable to NIST. The FSA-K2 Force/Displacement Testers are complete test systems which can be configured for a number of applications requiring both force and displacement measurement.

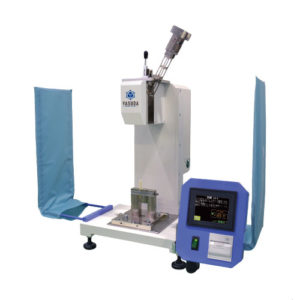

No.268 UNIVERSAL IMPACT TESTER

This pendulum type Charpy impact tester can automatically conduct the test cycle, and is capable of testing at extremely low temperatures (as low as -70°C). Test conditions are inputted via touch screen and a maximum of 210 specimens can be tested continuously. Due to the high capability of the refrigerating system, it is both time and cost efficient when compared to any other model.

No.258-ZA IMPACT TESTER (FULL AUTOMATIC)

This is the fully automatic version of the IMPACT TESTER (Charpy and Izod). A maximum of 210 impact tests can be continuously conducted just by setting the test specimen to the preparation cassette and inputting the test conditions in the computer software. The test specimen will automatically come out from the preparation cassette which is located inside the low temperature chamber. The test specimen will be impacted within 5 seconds after it comes out from the preparation cassette.

No.258-L IMPACT TESTER (WITH REFRIGERATING MACHINE)

This tester enables the operator to conduct the Charpy and Izod impact tests in a low temperature condition. The low temperature chamber is double-doored and the inner door is equipped with working gloves so that the temperature inside the chamber is kept constant while the operator is attaching the test specimen.

No.258 IMPACT TESTER

This pendulum type impact tester for plastic enables the operator to conduct both Charpy and Izod impact test just by changing the hammer and the anvil. The tester can be attached with an optical rotary encoder, so that the impact data can be saved in a computer. ↑ DIGITAL/TP TYPE

No.119-L DE MATTIA FLEX-CRACKING AND CRACK GROWTH TESTER (WITH REFRIGERATING MACHINE)

This tester is used to measure the appearance of cracks and the growth of the cracks to vulcanized rubber and thermo-plastic rubber by adding repetitive bending stress. The test is conducted by setting the test specimen to the parallel allocated Chuck and adding repetitive bending stress.

No.119-L-VR DE MATTIA FLEX-CRACKING AND CRACK GROWTH TESTER (WITH REFRIGERATING MACHINE/ PICTURE BRE

This tester is equipped with a super-high-speed camera, which enables the operator to observe and save the appearance and the growth of the cracks. Since the test can be monitored by the super-high-speed camera, the test can be run without any discontinuance.

No.119 DE MATTIA FLEX-CRACKING AND CRACK GROWTH TESTER

This tester is used to measure the appearance of cracks and the growth of the cracks to vulcanized rubber and thermo-plastic rubber by adding repetitive bending stress. The test is conducted by setting the test specimen to the parallel allocated Chuck and adding repetitive bending stress. The tester can also be assorted with a low temperature oven (L type).

No.145-SV CREEP TESTER (SERVOMOTOR TYPE)

Adding a servomotor to the usual actual load type creep tester, and detecting the load using a load cell, the servomotor type creep tester can effectively reduce impact when the test specimen breaks, simultaneously saving space. By choosing the Chuck, the tester enables conducting tensile stress relaxation tests and the condensation stress relaxation test. The tester can also be assorted with test functions such as thermal contraction testing and thermal impact testing.

No.145-A/No.145-B CREEP TESTER (PULLEY TYPE/ BALANCE TYPE)

This tester is used to measure the increasing creep by applying static load to plastic test specimens. By choosing the Chuck, the tester enables to conduct tensile test, condensation test, and bending test. The tester can also be assorted with test functions such as relaxation test, heat shrinkage test, and thermal impulse test.

No.120-LABOT MELT FLOW INDEX TESTER (FULL AUTOMATIC)

This tester is equipped with robotic mechanism which enables fully automatic melt flow index tests up to a maximum of 50 samples (standard of 12 samples). The test conditions and the outputs can be set and observed through the computer software. Details of No.120 LABOT MELT FLOW INDEX TESTER (FULL AUTOMATIC)≫

No.120-SAS MELT FLOW INDEX TESTER (AUTOMATIC)

This tester is used to measure the melt flow index of thermo-plastic. The melt flow index is acquired from the weight or the volume of the extruded specimen at a specified cylinder temperature and with a specified load of piston through the die.

No.120-FWP MELT FLOW INDEX TESTER (MANUAL)

This tester is for measuring the melt flow index of thermo-plastic. The test can be conducted easily, from setting the test condition up to data analysis, using a 5.7” full color touch panel.

No.101-H TABER TYPE ABRASION TESTER

JIS A1453、(K5400)、K5600-5-8/9、K5665、K6264-2、K6404-4、K6902、K7204、(L1018)、L1085、L1096、ASTM D1044、TAPPI-T476、JAS、(JASO-M403)、ISO 4649、5470-1、7784-1/2、9352